10 Advantages and Disadvantages ] of Direct-to-Garment

DTG - Direct-to-Garment has become an important part of the print and fashion industries. It allows images and designs to be printed directly onto fabric products with high detail and quality

Advantages of DTG - Direct to Garment:

1- High quality printing:

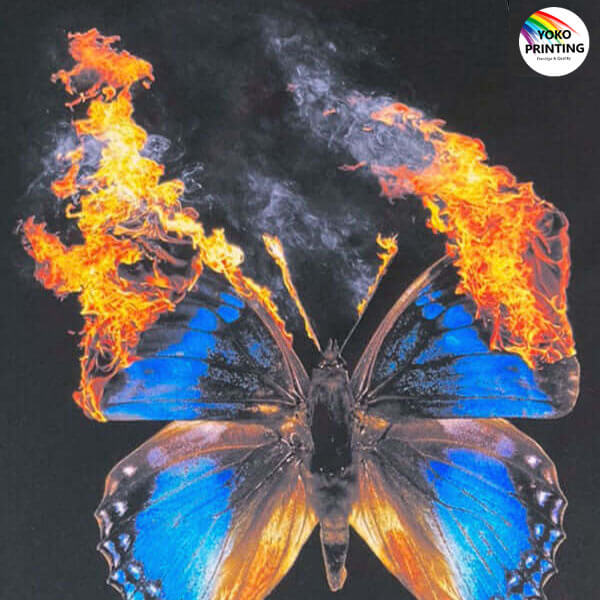

This technology can print images and details at extremely vivid high resolutions, creating products with outstanding, crisp print quality on fabrics.

Finished product printing drawing

2- Color variety:

DTG printing enables accurate color reproduction and an unlimited number of colors, allowing complex designs in multiple colors to be perfectly reproduced.

Machine direct to garment printing

3-Fast production time:

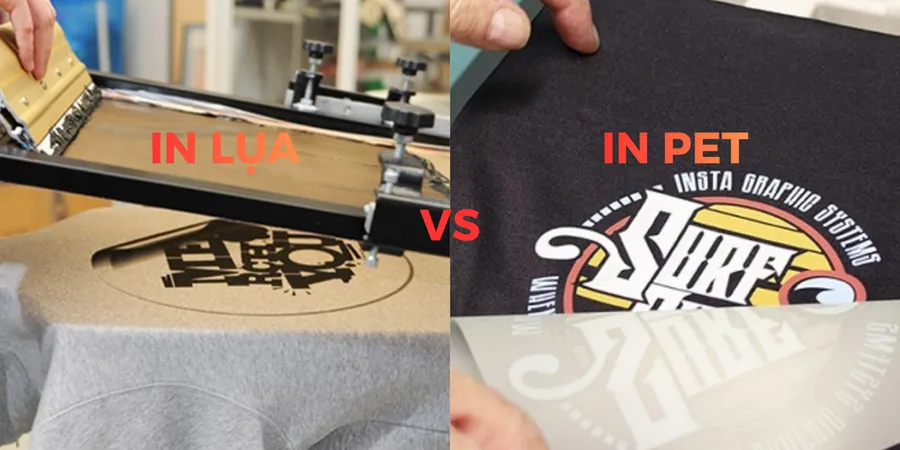

The printing process is fast and efficient, shortening production time compared to other printing methods such as screen printing, and an image can be printed in an average of 30 seconds.

4-High flexibility and customization:

DTG printing technology allows the flexibility to print customized designs, from printing personal images to changing colors and sizes according to customer needs, with no quantity limit.

5-Save ink:

DTG printing is more ink-efficient than many other printing methods, helping to reduce overall production costs.

Disadvantages of DTG printing technology:

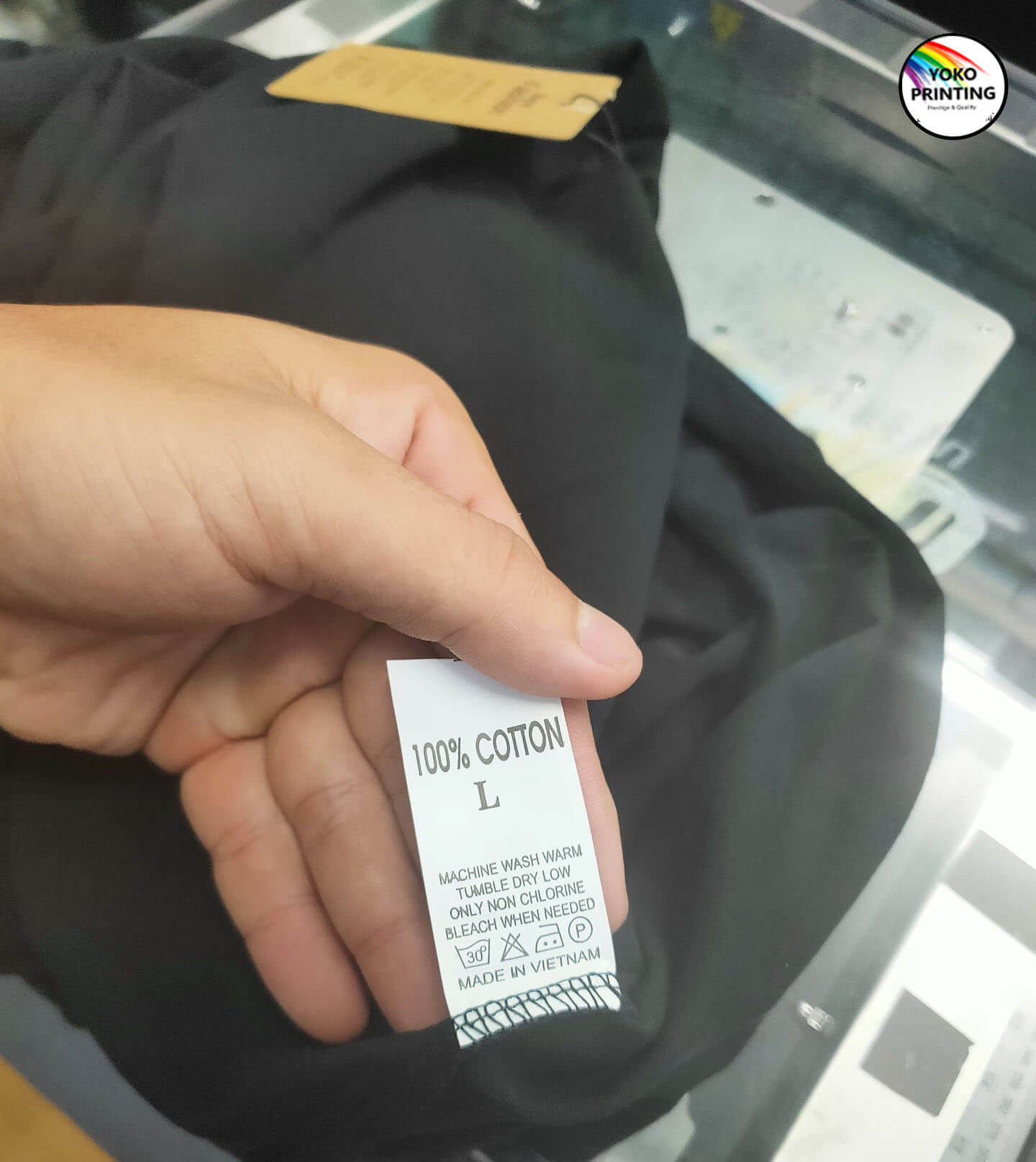

6 Printed material restrictions:

Usually works well on 100% cotton natural fiber fabrics, but can be difficult and unstable when printing on synthetic fabrics or specialty materials.

100% cotton T-shirt

7- High initial investment cost:

The initial investment cost of printers and DTG ink is very large, especially for small and newly established businesses. To own a standard printer, the price of the machine is about 350 million or more.

8- Print size restrictions:

Compared to some other printing methods, DTG printers have print size limitations that limit the ability to print on large or uneven products, with a maximum print size of 50x35 cm.

9-Technical requirements:

Achieving the best print quality requires knowledge and technical capabilities in printer adjustment and color management, and in terms of fabric processing, a German special waterjet machine worth 150 million must be used for jetting.

Special water spray machine

10- Not as durable as other printing methods:

On some fabrics and under certain usage conditions, DTG printing may not be as durable as heat transfer pet printing or heat transfer decal printing, screen printing.

In short, Direct-to-Garment brings a lot of benefits, especially for large fashion houses and on-demand printing. However, careful consideration is required to fully utilize this technology and effectively address its limitations.

In our factory, we have been printing dtg for more than 3 years and experienced countless failures before finally sharing the above with you. If you want to test printing, please contact us and we will share more details.

Contact: Text/Call 👉 ZALO link/phone number 0913711079 (Factory owner Kien)

References : https://en.wikipedia.org/wiki/Direct-to-garment_printing

Xem thêm